Low frictional resistance – Whether stopped or in motion under any operating conditions, a film of high pressure oil between the spindle and spindle bearing ensures there is zero direct metal to metal contact. The only resistance to spindle motion is oil viscosity. This saves energy and results in longer working life of the spindle.

High rotational accuracy – The film of high pressure oil evenly distributes and maximizes load bearing capacity, and evens out any errors that occur over the course of grinding. Generally, any errors caused by hydrostatic bearing motion are only 1/3 of bearing surface errors - resulting in higher rotational accuracy.

High rigidity even during heavier than normal loading and low eccentricity.

High pressure flow of spindle oil reduces spindle heating.

Excellent stability – The film of high pressure oil has a damping effect that maximizes stability and, as a result, surface finish quality of the work piece.

The grinding wheel, regulating wheel, and tailstock used in this series all employ hydrostatic spindles. Spindle concentricity is within 2 µm on all spindles. These grinding machines are built for optimal precision and efficiency.

This series employs the CBN grinding wheel with high linear velocity of 100m/sec for high efficiency and high precision grinding. The CBN grinding wheel is very wear resistant, and greatly reduces contaminants related to grinding wheel wear and vastly improves efficiency. Moreover, by using the CBN grinding wheel, power requirements for the spindle motor are effectively reduced, saving you electricity and money.

The flexible spindle design is meant to deliver customer specific requirements. Three designs of grinding wheel spindle are available:

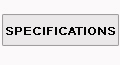

1) Two Sided Dual Spindle Cylindrical Grinder. Please refer to our catalog or the image on this page PAT NO D 123381.

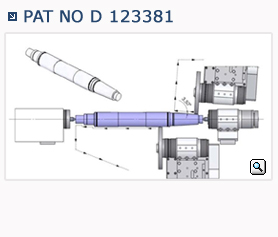

2) Dual Workstation Moving Spindle Grinder. Please refer to our catalog or the image on this page PAT NO D 123382.

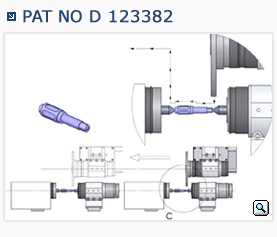

3) Dual Spindle Grinder. Please refer to our catalog or the image on this page PAT NO D 123383.

All design concepts are based on control of grinding wheel spindle motion to maximize design flexibility.

|

|

|

Spindle modularization is aimed at improving the work piece grinding process. Flexibility changes the machine structure and optimizes the machine to best satisfy user needs.

The spindle drive design means the work piece is absolutely stable during grinding. The automatic feed system, measuring system and peripherals greatly enhance ease of use, adjustment and maintenance, and overall user convenience.

German Mahr Roundness

Tester

German Mahr Surface

Roughness Tester

Test Staff